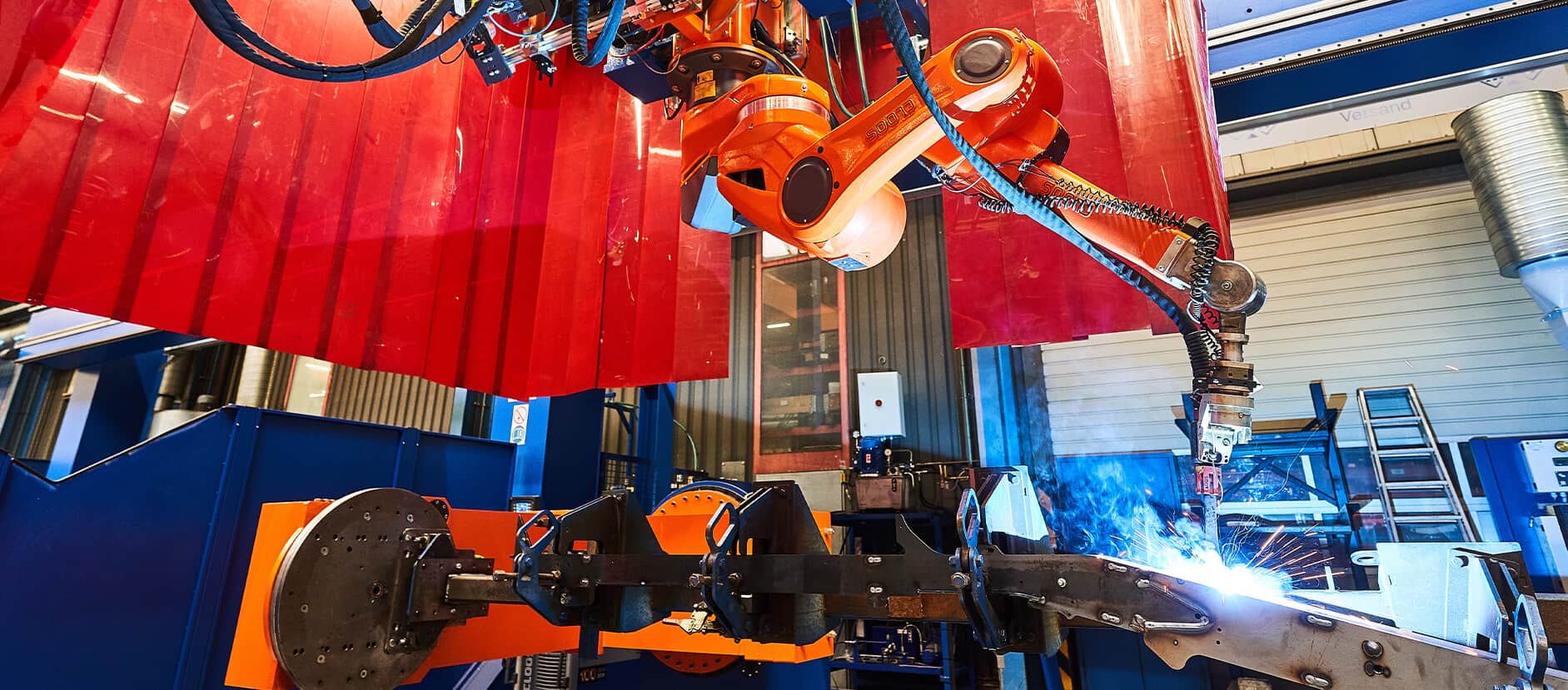

Benefit from MBH robot welding!

Constant investments in our machine park guarantee our customers and us a competitive advantage. Our modern systems for automated welding are unbeatable, especially for medium and large series. We are experts when it comes to complex chassis and component construction as well as frame constructions of all kinds.

If you want to know more about the performance data just ask Mr Pliet. He will have an answer to every question!